CMO

If you are not happy with your CMO, it is the right time to consider BORYUNG as your new partner.

BRing your product, BORYUNG will BRing you success.

Boryung has served over 60 years in the pharmaceutical industry, especially with oral solids and injectables. Being No.1 Company in oncology products in South Korea, we bring both enhanced quality and reliability to our customers. With our state-of-the art facility, we will always be at the forefront of bringing best quality of products from clinical to commercial scale for our partners. Your best CMO partner, Boryung will bring the greatest success for you wherever you aim.

WHY BORYUNG?

-

PIC/S GMP

PIC/S GMP

-

HIGH QUALITY OF

HIGH QUALITY OF

DEVELOPMENT SKILL -

GLOBAL BUSINESS

GLOBAL BUSINESS

COOPERATION OVER

150 PARTNERS

WORLDWIDE -

STATE OF THE ART

STATE OF THE ART

FACILITY CONSTRUCTED

IN 2018 -

EXCELLENT QUALITY

EXCELLENT QUALITY

CONTROL SYSTEM -

STRONG

STRONG

COLLABORATION

WITH BORYUNG'S SMEs -

DOCUMENTATION

DOCUMENTATION

INTEGRITY

FOR SUBMISSION -

WORK TOGETHER

WORK TOGETHER

ON COST REDUCTION

CYTOTOXIC MANUFACTURING CAPABILITY

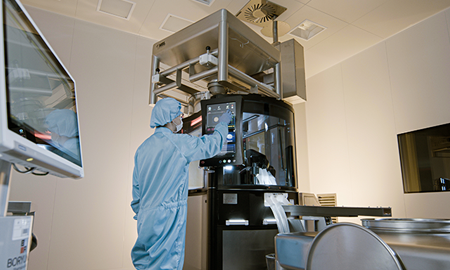

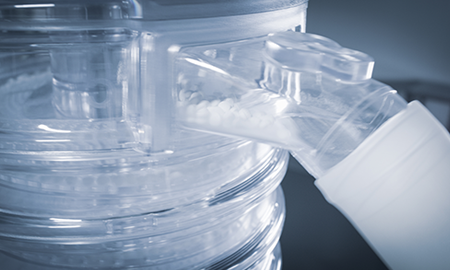

The new oncology manufacturing facility has the capacity of producing 5.7 million vials per year for solution and 0.4 million vials for lyophilized products. Our facility ensures safe environment for all operators from cytotoxic active substances using a closed manufacturing system. Assurance on optimized quality and quantity will be at your benefit with our automatic warehouse system. Discover our full CMO/CDMO service with our team of experts and high-quality facilities which will be great for your future.

The injectable facility at Yesan Campus is dedicated to highly potent active pharmaceutical ingredients (HPAPIs), especially cytotoxic agents. This cutting-edge facility of ours offers two parenteral manufacturing complexes capable of aseptically filling liquid and lyophilized products. Cytotoxic products have been known to be highly curative for tumor cells and for the treatment of various types of cancer by directly destroying cancer cells. However, they can also have detrimental effects on other remaining cells and incur unwanted events. Therefore, manufacturing of cytotoxic oncology product requires an isolated facility to protect all personnel and also an expert team to control the facility. Our highly skilled team and isolation system (as low as OEB 5) will exceed your expectations.

- Manufacturing of Cytotoxic Oncology Products

- Liquid and Lyophilized Products

- Fully Dedicated Production Lines

- Aseptic Process

- Isolation System Covering OEB 5 (<1 μg/㎥)

- Fully Automated CIP/SIP

- Vials from 1 mL to 70 mL

- Flexible Batch Sizes from 5 L to 500 L

- Labelling and Packaging

- Fully Automated Storage Including Cold Chain

- Analytical Testing

- Analytical Method Validation

- ICH Stability Studies

- Microbial and Sterility Testing

ORAL SOLID DRUG MANUFACTURING CAPABILITY

With our brand new facility and years of accrued expertise will deliver your products time efficiently and optimize your product formulation. At Yesan campus, our capacities extend up to producing 480 kg of bulk powder and granules. Our high-speed compression, coating and inspection machines also enable us to manufacture large batches of tablets in both single-layer and multi-layers. This advanced facility equipped with a spine which can easily extend the facility based on your demand and production scale.

With over 30 years of experience in manufacturing and development of Oral Solid Drugs, we will enhance your product quality by establishing robust manufacturing process and customizing your products' needs. Meet our experts and your products will be brought in time and with the best quality you can expect.

- Formulation Development

- Trouble Shooting

- Wet and Dry Granulation

- Compression in Both Single Layer and Multi-Layer

- Film Coating

- High speed blister (Alu-Alu) packaging capability

- Fully Automated Storage

- Analytical Testing

- Analytical Method Validation

- ICH Stability studies

- Microbiology